Simulation and machine learning for high-precision dimensional microscopy (SiM4diM)

In many industrial sectors, optical microscopes are used to measure micro- and nanostructures, as they enable non-destructive and rapid inspection of manufacturing processes. Due to wave-optical effects, such as light diffraction at object edges or unavoidable imaging errors of the optical system, objects are always blurred to a certain degree leading to a limited accuracy in the micrometre range. In order to increase the accuracy of existing optical measurement methods and to localise object edges with an accuracy of less than one micrometre, a novel software-based method is to be developed that effectively compensates for wave-optical effects and imaging errors.

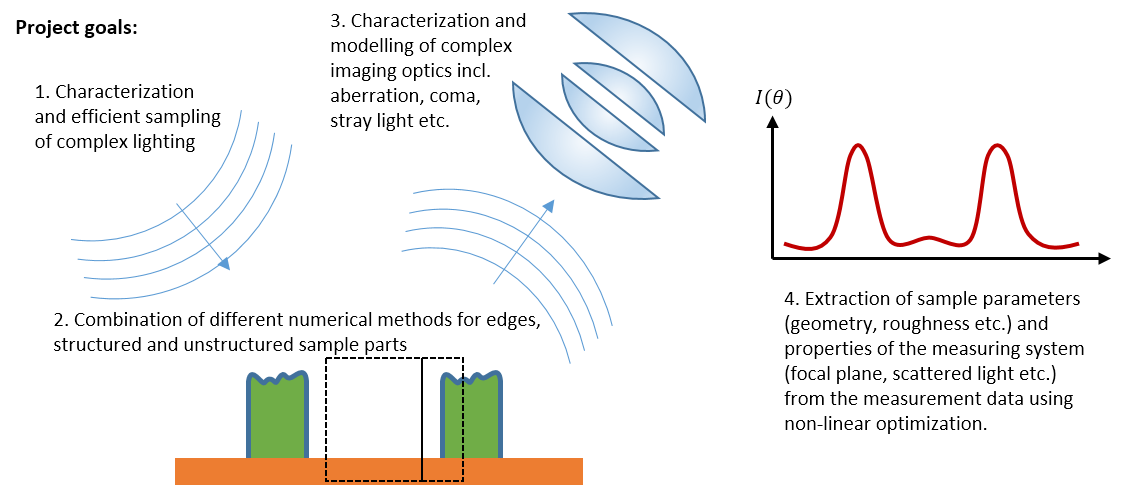

The targeted method is based on an exact numerical simulation of the entire imaging process. This includes the simulation of the frequency and angular distribution of the illumination, the scattering of the electromagnetic fields at the object to be measured, the optical magnification and the digital measurement of the image. By simulating the process with different sample parameters - e.g. edge position and height or refractive index of the measurement object - those sample parameters can be determined which best fit the measured signal.

Partners:

Physikalisch Technische Bundesanstalt, Braunschweig, Germany Working group Optical Nanometrology

Hochschule Aalen, Aalen, Germany Zentrum für Optische Technologien

Carl Zeiss Industrielle Messtechnik GmbH, Oberkochen, Germany (associated partner)

JCMwave GmbH, Berlin, Germany

Funded by:

German Federal Ministry of Education and Research (BMBF). Grant No. 01 IS 20 080